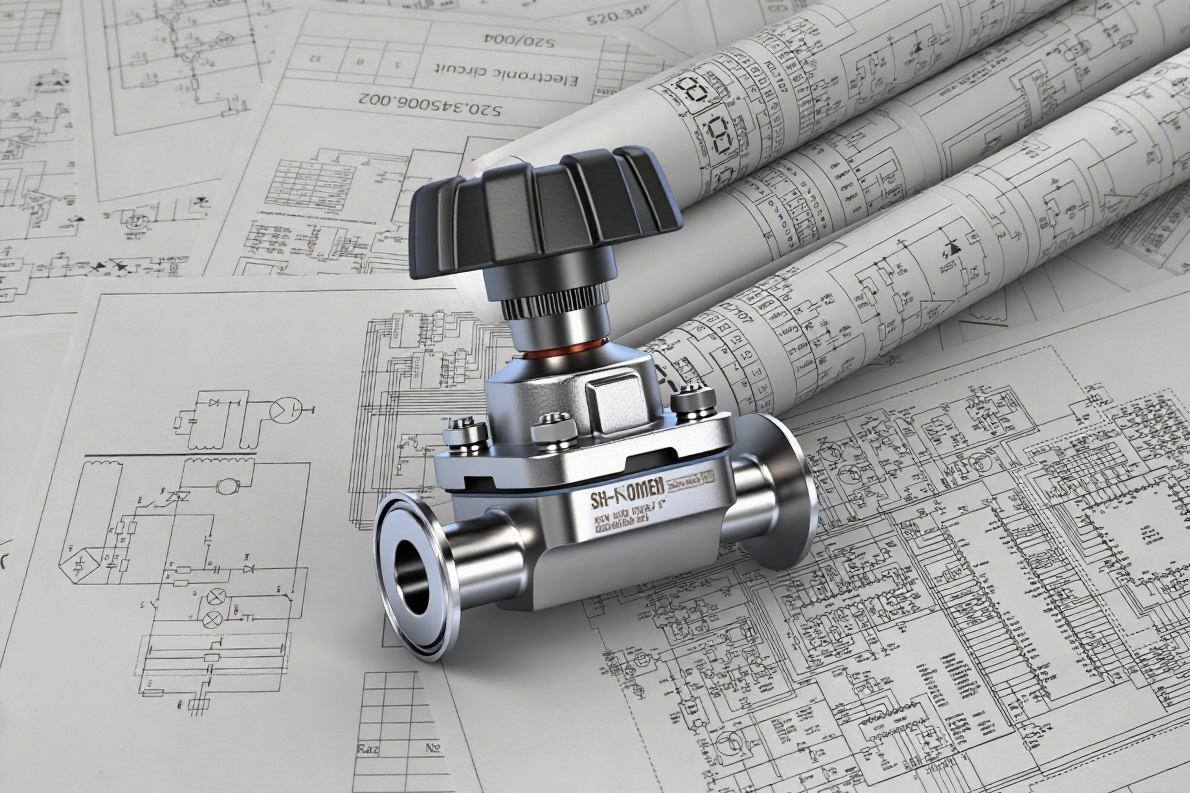

See more information about SH-NOMEN and learn more about the use of valves

Sanitary valve standards, also known as sanitary valve standards, refer to the relevant standard requirements for valves used in fluid process systems used in food, medicine, bioengineering, and other fields.

Sanitary Valve Standards – Key Requirements

1. Materials

• Wetted parts must comply with food- and pharma-grade standards (e.g., 316L stainless steel, PTFE) to eliminate any risk of product contamination.

2. Valve Design

• Full-bore construction minimizes dead legs and simplifies CIP/SIP.

• All internal surfaces are mirror-polished or precision-blasted (Ra ≤ 0.8 µm) to reduce biofilm formation.

3. Sealing

• Leak-tight sealing is mandatory. FDA-compliant elastomers such as silicone or PTFE are standard.

4. Cleanability

• Internal geometry optimized for complete drainability and residue-free cleaning; design must support rapid CIP/SIP cycles.

5. Manufacturing Standards

• High-precision machining aimed at bioprocessing applications; 304/316 stainless steel is standard.

• Relevant norms:

– U.S.: 3-A SSI Standards

– Europe: EHEDG Guidelines

– China: GB/T 12224 and related GMP annexes

These standards provide clear design, fabrication and testing criteria, ensuring sanitary valves deliver safe, reliable performance in food, beverage and pharmaceutical processes.