See more information about SH-NOMEN and learn more about the use of valves

Reverse Osmosis (RO) is widely used in pharmaceutical water-treatment systems and is the core process for producing both Purified Water (PW) and Water for Injection (WFI) that meet pharmacopoeial standards. In this article, we will explain what RO is, how it works, and key performance indicators such as system recovery.

1. What can an RO membrane remove?

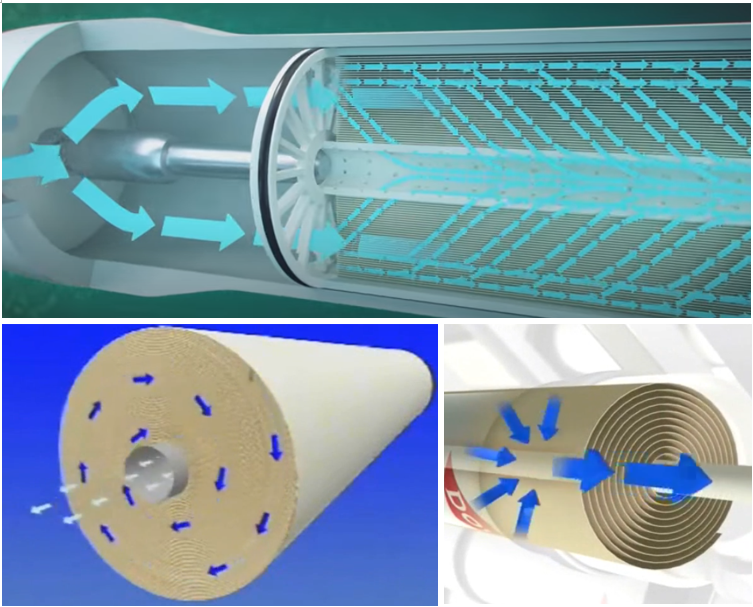

A reverse-osmosis membrane is a semi-permeable barrier that permits certain substances to pass while blocking others. Acting as the heart of the RO process, it purifies water by rejecting dissolved solids, bacteria, viruses, and other contaminants. Its semi-permeable nature allows water molecules to permeate, yet retains larger molecules and ions—this selective permeability is what makes RO so effective for water purification.

2. What is an RO membrane?

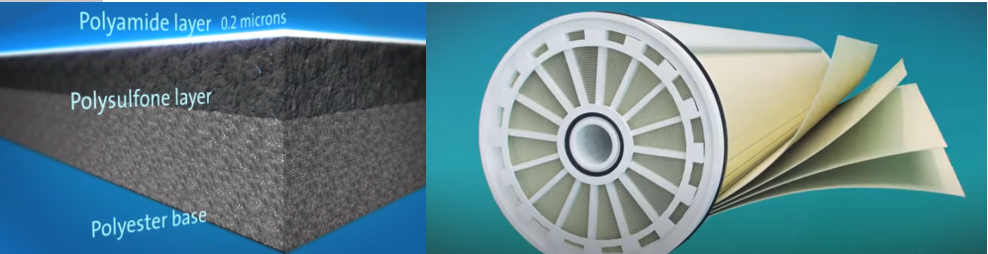

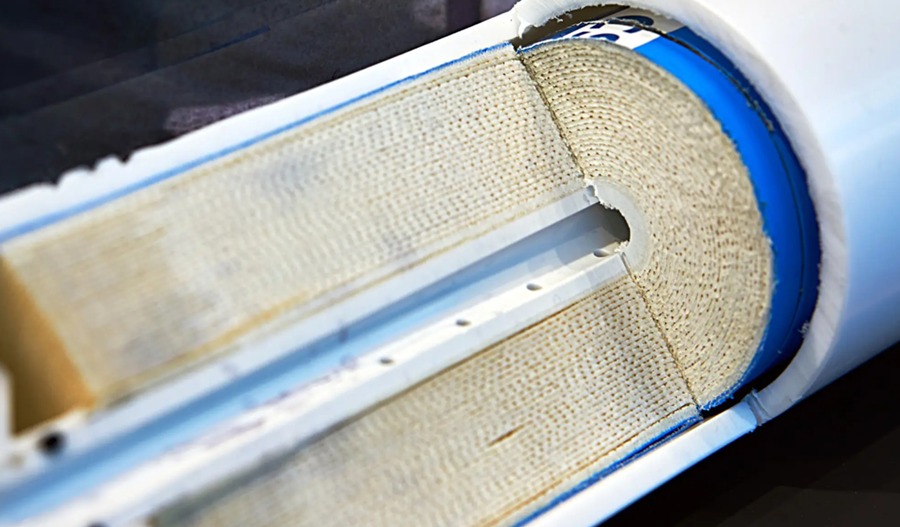

Industrial RO membranes typically consist of three polymeric layers:

• a non-woven fabric support,

• a polysulfone microporous layer, and

• a thin-film composite desalination layer.

3. How does reverse osmosis work?

Reverse osmosis is a water-purification process that uses a semi-permeable membrane to remove impurities. It reverses the natural phenomenon of osmosis by applying external pressure. In natural osmosis, water migrates through a membrane from a region of lower solute concentration to one of higher concentration. In RO, pressure is applied to the high-concentration side, forcing water molecules in the opposite direction—toward the low-concentration side. This reversal causes the membrane to retain dissolved solids, organics, bacteria, and other contaminants, yielding purified water on the downstream side.

4. How Reverse Osmosis Works

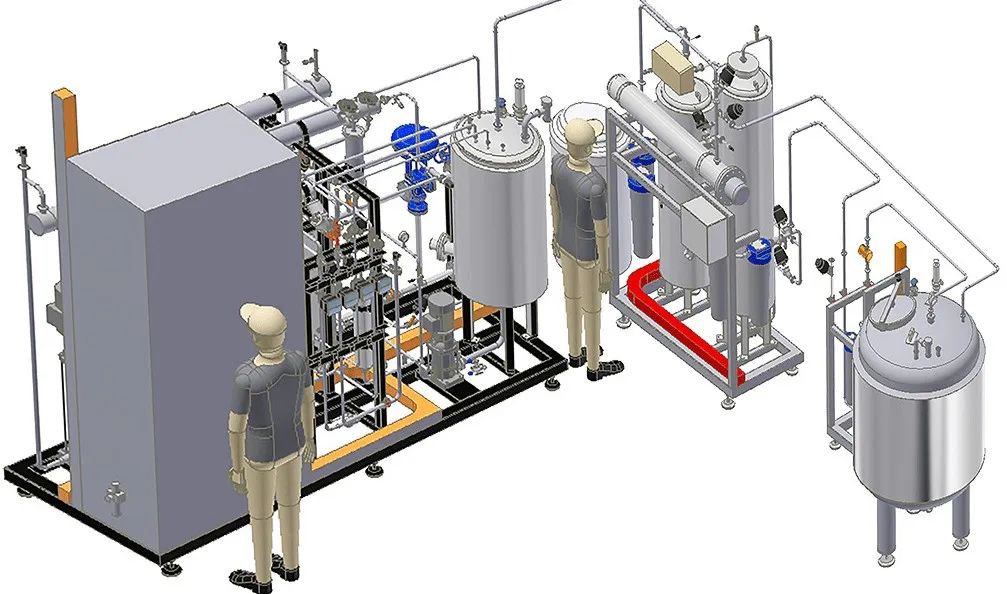

A reverse-osmosis system consists of multiple filtration stages to ensure effective purification. The process typically includes pre-filtration, membrane filtration, and post-filtration. During pre-filtration, sediments and larger particles are removed to protect the membrane. Water then passes through the semi-permeable membrane, where dissolved solids, chemicals, bacteria, viruses, and other contaminants are rejected and separated from the purified water.

5. RO System Recovery Rate

Recovery rate is the ratio of permeate (purified water) produced by an RO system to the total feedwater supplied. It is a key performance indicator that determines overall process efficiency. A higher recovery rate means a greater proportion of feedwater is converted into purified product, while the remainder is discharged as concentrate. Optimizing this balance is essential:

• Water conservation – higher recovery reduces waste.

• System efficiency – recovery directly affects membrane fouling, energy use, and impurity-removal capability.

• Water quality – excessively high recovery can raise concentrate solute levels, compromising permeate purity.

Therefore, every RO system must be engineered and operated at an optimal recovery rate tailored to the specific feedwater composition and final application requirements.

Source: PharmaEng Compliance Notes